Bandsaw Box

Holzmann Maschinen

The most common application for band saws is woodworking. This machine allows you to do many amazing things with wood.

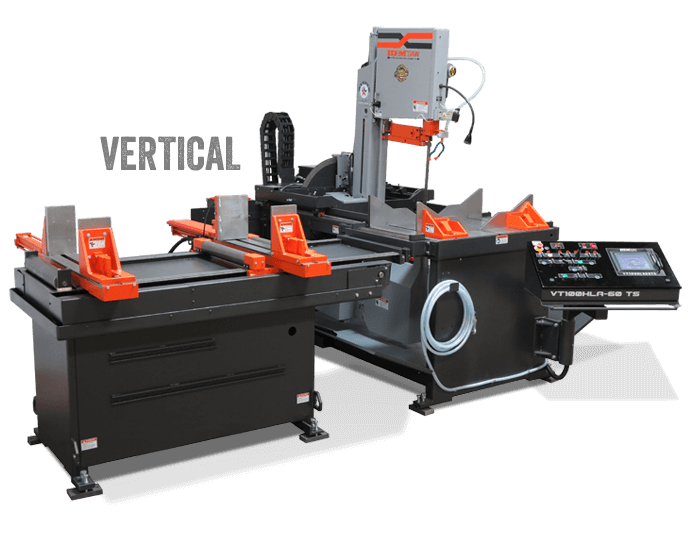

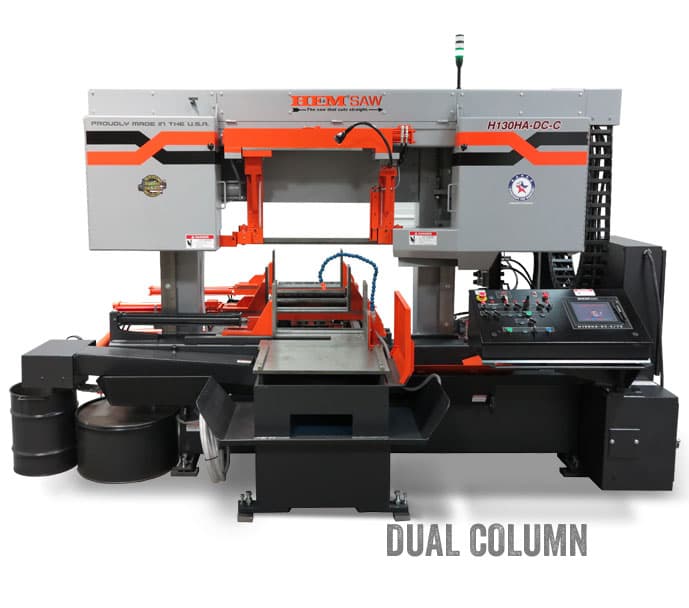

Generally, horizontal bandsaws can be found on the floor. They can be used to cut basic shapes with different materials.

Bandsaw Box